1, preface

HJZ series reducer is a special reducer for roller drive unit of casting mill. It is a new reducer developed by our company on the basis of transmission principle. It is a major breakthrough of double planetary gear reducer.

2, types, characteristics and scope of application

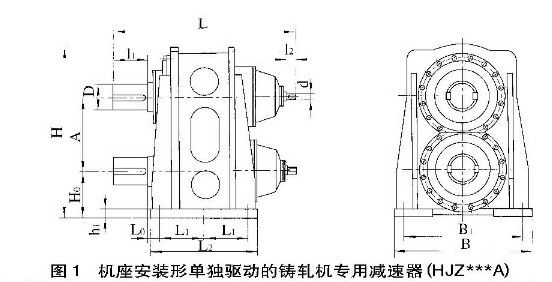

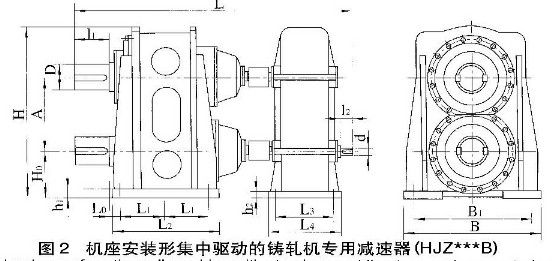

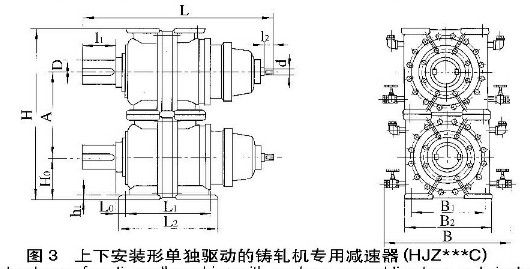

There are two types of special reduction devices for roll drive of casting mill. Namely: stand mounting type (see Figure 1, figure 2) and up and down mounting type (see Figure 3 and Figure 4). There are two types of special drive for roller drive in casting mill. That is, a separate drive driven by multiple motors (without a shunt box, as shown in Figures 1 and 3) and a motor driven centralized drive (with a shunt box shown in Figure 2 and Fig. 4). Cast rolling mill special reducer drive alone form simple transmission device. The roller speed control devices, can be used for different roll diameter, roll speed cast rolling mill., centralized drive form than driving many forms of diversion box, use it to replace the single drive type electric control device. In terms of economic indicators, a transmission device with a single drive is recommended. The individual drive forms and centralized drive forms of special speed reducers for casting mills are applicable to the rolling working state of any casting mill. For cast roller in wear condition in the work, independently driven form casting rolling mill special reducer by adjusting the rotational speed of the motor to ensure the roller speed is the same, so as to ensure the surface quality of the rolled workpiece. The individual drive form can be used not only for rolls of the same diameter but also for rolls of different diameters (not only of diameter wear). The centralized drive type is only suitable for the casting mill with the same roller diameter. When the surface quality requirements of the product are high, the roll speed can be guaranteed only by correcting the roll diameter.

3, the main technical parameters

The main technical parameters of the special reducer for casting mill are shown in table 1.

4, shape, installation size

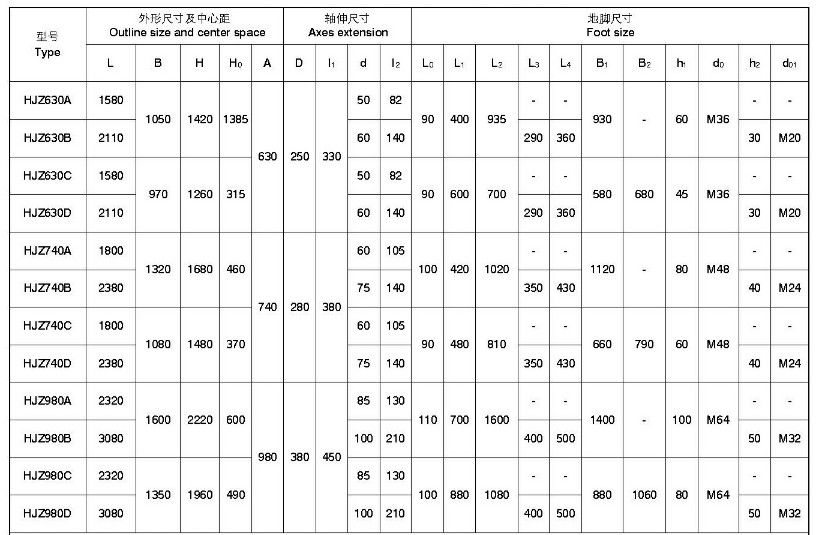

For the special reducer of casting mill, the dimensions of installation shall be shown in table 2.

表2 外形、安装尺寸

5, selection method

The selection method of special speed reducer for casting mill is to select the center distance of roll and the required rolling torque and roll speed of casting mill.

For example, a rolling mill with a roller center of 960mm is required. The rolling torque required for the rolling screws is 2 x 400kN.m, and the roll speed is 0.84r/min. Table 1. selects the HJ2980 drive.

6 、 installation, use and maintenance

The connection between the reducer in the transmission and the motor and the working machine uses an elastic coupling, a toothed coupling or other nonrigid couplings. And carefully and carefully adjusted to ensure the assembly accuracy.

It is strictly prohibited to strike or shock the assembly so as not to damage parts such as seals, retaining rings and bearings.

Before the gear reducer is put into use, make sure that the reducer is injected with the required lubricating oil. In any case, the oil level of the reducer can not be lower than the minimum position of the oil mark.

The installed reducer must be loaded before commissioning. Empty running before load test 2h. Begin load test in case of air transfer to normal. When the conditions permit, the following four stages should be loaded step by step:

The first stage is 25% of the rated load

The second stage is 50%. with rated load

The third stage is 75%. with rated load

The fourth stage is 100% of the rated load.

For field conditions, it is impossible to load progressively, and at least 2H and full load operation 4H must be carried out.

Special reducer for casting mill adopts oil tank lubrication. For the first time, when the reducer is running 300-600h, the oil must be replaced. Drain the lubricating oil after the retarder stops and the oil is not cold. Thereafter, whenever the reducer works, the 1500-5000h is replaced, which is mainly determined by the working environment. However, the time interval for each replacement of the lubricant should not exceed 18 months. The reducers should be replaced with lubricating oil of the same grade, and lubricants from different grades or different factories must not be used together.